Capabilities

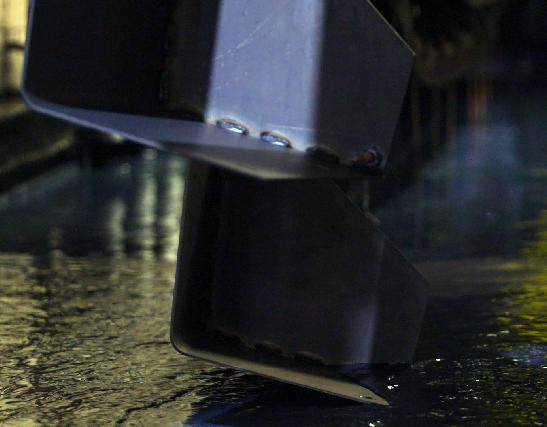

E-Coat

Electrocoating (E-coat) is a durable, eco-friendly finishing process that delivers superior corrosion resistance and even coverage—even on complex shapes. Using an electrically charged paint bath, it bonds evenly to every exposed surface, creating a smooth, long-lasting layer of protection.

Key Benefits

- Superior corrosion resistance

- Uniform coverage, even in recessed areas

- Durable, chip-resistant finish

- Cost-effective with high production efficiency

- Eco-friendly, water-based technology

Whether used as a standalone coating or as a primer for powder or liquid topcoats, E-coat ensures your products are built to last.

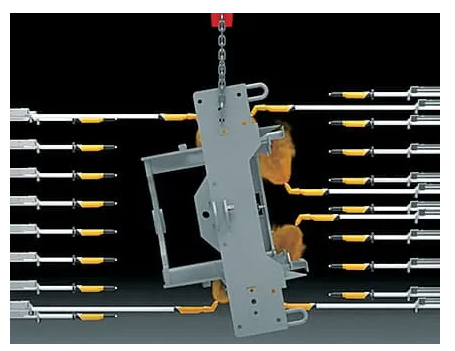

Topcoat with Dynamic Contouring Technology (DCT)

Our advanced topcoat system with DCT (Dynamic Contouring Technology) adapts to the unique shape of each part, ensuring consistent coverage across edges, corners, and complex contours. The result is a finish that combines premium durability with superior appearance.

Key Benefits

- Adaptive coverage on sharp edges and recessed areas

- Long-lasting protection against corrosion and wear

- Consistent film build without thin spots or excess material

- Smooth, uniform finish for enhanced aesthetics

- Efficient, sustainable process with reduced waste

From automotive to industrial applications, our DCT topcoat delivers performance, protection, and a flawless look—every time.

Nine-Stage Wash System

A flawless finish starts with a clean foundation. Our nine-stage wash system removes oils, dirt, and contaminants while preparing metal surfaces for maximum adhesion and long-term performance of both E-coat and topcoat finishes. Each stage is precisely engineered to ensure consistency, durability, and superior corrosion resistance.

The Result

A meticulously prepared surface that ensures coatings bond effectively, last longer, and perform even in the harshest environments.

Pro-Active Quality with Mil Thickness Verification

At CWF, quality is never left to chance. We use mil thickness guns throughout our finishing process to verify coating thickness in real time—ensuring every part meets exact specifications.

How It Works

Mil thickness guns measure coating film build with precision. This confirms parts are coated correctly—thick enough to prevent corrosion, but not so thick that it risks cracking or appearance issues.

Key Benefits

- Consistent Results – Uniform film build for predictable performance

- Improved Durability – Proper thickness enhances corrosion resistance and longevity

- Reduced Rework – Early detection of variances keeps projects on schedule

- Customer Confidence – Documentation and verification prove coatings meet industry standards

By combining advanced tools with trained inspectors, we take a proactive approach to quality—delivering finishes that not only look great, but perform even better.

CARC Paint Capability

At Central Wisconsin Finishing, we are proud to offer CARC (Chemical Agent Resistant Coating) paint finishing – the military standard for protective coatings.

What is CARC? CARC is a highly durable polyurethane coating designed to withstand some of the harshest environments. It resists chemical agents, prevents absorption of contaminants, and is formulated to perform under extreme wear and exposure.

Why Choose CARC?

- Military-Grade Protection – Approved for use by the U.S. Department of Defense and applied on tactical vehicles, equipment, and defense components.

- Corrosion & Chemical Resistance – Protects against corrosion, chemical contamination, and weathering for long-lasting performance.

- Durability in Harsh Environments – Maintains adhesion and appearance under demanding operational conditions.